Overview

This Hospital* is located in the mid-Atlantic region of the United States. Hospital set a goal to reduce energy consumption and GHG emissions while maintaining a high level of air quality and patient comfort. To this end, Hospital was interested in implementing energy conservation measures and technologies, which help

achieve these goals while considering their specific needs as a healthcare facility.

* Due to confidentiality agreements, we are not able to provide the client name. We will refer to the firm as Hospital throughout this case study.

Cimetrics’ Solution

Cimetrics was selected to provide its Analytika Pro solution for Hospital. Within the 2.1 million square feet monitored by Cimetrics, there are operating rooms,

research labs, vivariums, and offices. Cimetrics collaborated with the hospital and their building automation system provider to connect to and collect sensor and actuator data from over 59,000 physical points. Data was collected every 15 minutes, 24 hours a day, 365 days a year, for a total of approximately 5.7 million data samples per day. The following systems were monitored: 135 Air Handling Units, 2 Chillers, 187 Heating & Cooling Pumps, 82 Fume Hoods, 4,820 Terminal Units, and other miscellaneous equipment.

Over 2,000 Analytika software algorithms then analyzed the data to identify opportunities to reduce energy, improve environmental conditions, maintenance,

operations and reduce regulatory costs. Analytika also uncovered apparent equipment problems, potential health & safety concerns, occupant comfort improvement, and operational uptime improvements. Experienced Cimetrics engineers leveraged Analytika software to identify opportunities, determine root cause, and calculate annual savings impact. Actionable recommendations were documented and provided to the client both through online and offline channels. Cimetrics’ role did not end at recommendations. Cimetrics engineers engaged with the client team on a

regular basis to help answer questions, coordinate implementation, and provide regular feedback on progress.

Results Achieved

Energy Savings Financial Summary:

- Energy Savings: $1,010,083

- Simple Payback: 0.46 years

- Net Present Value: $1,892,240

- Implementation rate of recommendations: 45%

Other Operational Benefits:

- Comfort improvement

- Maintain ventilation requirements

- Increased capacity of existing equipment

- Long-term reduction of work orders (LBNL study)

- Contractor & vendor management

- Compliance (internal and external reporting)

- Predictive maintenance

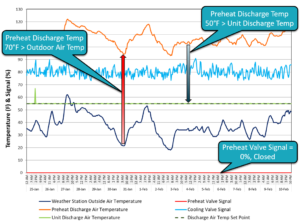

Simultaneous Heating & Cooling

The Air Handling Unit (AHU) preheat coil valve was leaking when signaled closed (0% valve signal), resulting in a preheat discharge temperature that was over 40

degrees warmer than the required temperature. As a result, the cooling coil valve opened simultaneously to maintain the final supply air temperature at its setpoint

of 55°F. The simultaneous heating and cooling resulted in excess heating and cooling costs.

This issue was not detected in the occupied spaces due to proper space temperature control and lack of comfort complaints; however, it was identified with Analytika.

Solution

Cimetrics worked with the controls vendor to repair the leaking preheat coil valve. This resulted in appropriate temperatures at all sensor locations using less cooling

and heating energy.

Energy savings for solution: $93,340

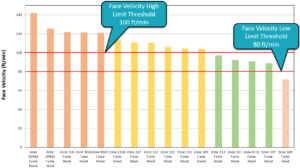

Fume Hood Face Velocity & Airflow

Cimetrics identified fume hoods that have face velocities greater than the high limit threshold of 100 fpm, which result in excess energy use, as well as face velocities below the low limit threshold of 80 fpm, which have safety implications.

Cimetrics also identified airflow setback opportunities to reduce energy use during unoccupied periods.

Solution

Cimetrics worked with facilities staff to optimize fume hood face velocity and airflow to ensure compliance with safety requirements while minimizing the economic impact.

Energy savings for solution: $2,641

Contact us to find out how the powerful Analytika technology can translate your system data into meaningful, actionable insight today!

Leave a Reply