Analytika is the result of a 20+ year investment in the development of hardware, software, and analytics around building systems and industrial processes. Here’s a look at some of the key components of the Analytika technology platform.

Analytika technology combines years of experience with world class software development. The result is a robust, secure, and scalable architecture. Analytika is the leader in the following areas: universal connectivity to physical systems, automated fault detection and root cause analysis, secure data collection and storage, topological system modeling. Through these capabilities, Analytika technology provides enterprise management and predictive analytics to leading organizations in Pharmaceuticals and Life Sciences, Higher Education, Healthcare, Industrial, Manufacturing, and Government.

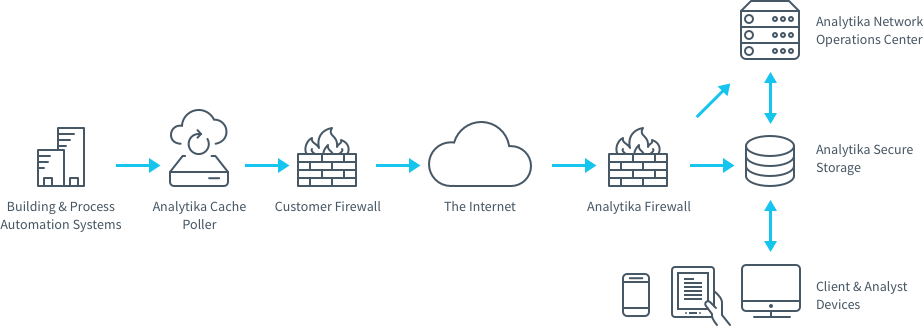

Simplified System Architecture

System Component Overview

Universal Connectivity

Analytika collection and analysis technology can connect to virtually any commercial building automation, metering, process automation system, industrial control, datacenter or renewable energy source regardless of vendor or geographical location.

Benefits:

- Analytika provides an integrated view of your systems.

- Our history in BACnet and other communication protocols allows us to connect to all of these subsystems without causing a negative impact on performance.

Automated Fault Detection and Root-Cause Analysis

We have codified our 22-year industry experience into over 2,500 proprietary algorithms that apply static and operational data for modeled systems. Our algorithms have been continuously tested and improved over our 22-year history. The result is the most complete and accurate fault detection and root-cause analysis technology on the market today.

Benefits:

- Know that your equipment is operating according to its specification.

- Know that your system meets cost, compliance and operational goals.

- The Analytika calculation engine will pinpoint the source of an issue and provide human-readable steps to resolve it.

Secure Data Collection and Storage

Our secure, scalable data collection and repository technology is capable of collecting and analyzing information from thousands of buildings worldwide over long periods of time.

Benefits:

- Cimetrics has an IT security process in place that has allowed us to serve mission-critical government and military, validated life sciences, research, health and financial institutions.

- All system data is stored for historical analysis and available for sophisticated, ad-hoc reporting. For example, FDA reporting in pharmaceuticals and life sciences.

- All stored system data is owned by the client.

Sophisticated Topological System Modeling

Our modeling technology supports the creation of systemic and equipment-centric models for a diverse set of systems, down to individual system points. This technology and the resulting model provide for rich, data-backed analysis and fault detection as well as the ability to construct “what if” scenarios in which the impact of a change to the system can be reasonably predicted.

Benefits:

- More accurate automated fault detection – the accuracy and depth of our models enable more sophisticated algorithms to be run on your system.

- Don’t be inundated by unnecessary alerts – our models allow the Analytika fault detection engine algorithms to pinpoint and alert on root causes and refrain from dispatching alerts for all of the nodes affected in the model tree.

Enterprise Management & Predictive Analytics

A large number of sensors and related data points in systems today combined with the Analytika data collection, modeling and calculation technologies enable organizations of all types to transition from a historical focus to a predictive management focus.

Benefits

- Analytika presents a bridge between real-time equipment and system level information and corporate management objectives.

- Allows management to predict and address quality, performance and efficiency issues before they lead to costly or catastrophic failure.

- What-if impact analysis. The Analytika model and sophisticated calculation engines enable you to build what-if scenarios to generate a data-based model of a potential outcome or impact to your system. For example, how would a failed temperature sensor affect a changeover cleaning process in a pharmaceutical production facility?

- Analytika provides the information and visualization necessary to prioritize and validate the efforts of your building automation, process control, commissioning and maintenance vendors.